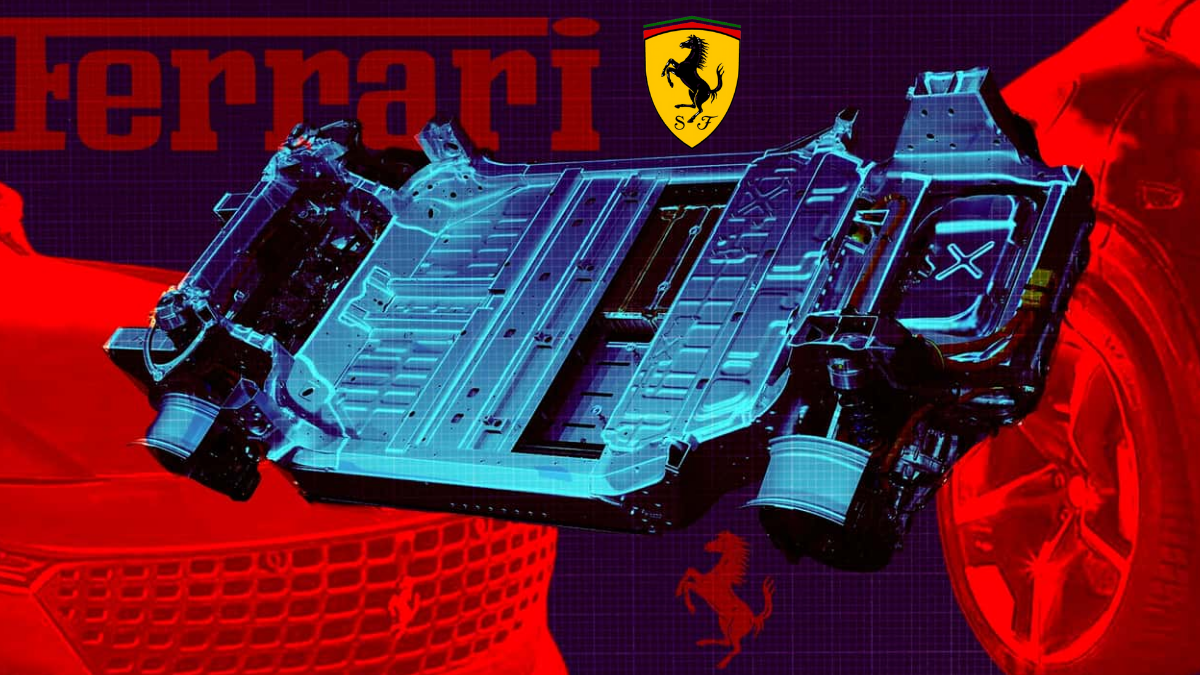

Ferrari has formally taken the wraps off the Elettrica EV platform the production-ready architecture that will underpin the brand’s first all-electric model and future battery-electric Ferraris. Unveiled at Capital Markets Day 2025, this platform represents the culmination of Maranello’s multi-energy strategy (ICE, HEV, PHEV, and now BEV) and decades of electrification research, from the 2009 F1-derived HY-KERS program and 599 HY-KERS prototype to the LaFerrari, SF90 Stradale, and 296 GTB. The Elettrica’s remit is ambitious: deliver authentic Ferrari driving emotion while introducing a new standard of electric performance and craftsmanship achieved through extensive in-house development and more than 60 patented technologies.

A Clean-Sheet EV for a Ferrari Driving Experience

Ferrari states that an all-electric model would only arrive once the technology could guarantee true Ferrari performance and feel. The Elettrica delivers via a ground-up EV platform designed around weight, stiffness, and energy management while preserving feedback, precision, and emotional connection. Key systems battery, e-axles, inverters, control software, and chassis elements are developed and manufactured in-house at Maranello to ensure integration and repeatable quality at Ferrari standards.

Short Summary

Item |

Details |

|---|---|

Platform |

Ferrari Elettrica (production-ready EV architecture) |

Peak Output |

>1,000 cv in boost mode |

Range (claimed) |

>530 km |

Battery |

122 kWh, ~195 Wh/kg pack energy density, 880 V system, up to 350 kW charging |

Axles |

In-house dual e-axles with Halbach-array rotors; peak inverter power >300 kW (front), >600 kW (rear) |

Chassis & Body |

75% recycled aluminum, saving ~6.7 tons CO₂ per car |

Dynamics |

Center of gravity 80 mm lower vs comparable ICE; 48 V active suspension (Gen 3) |

Performance |

0–100 km/h 2.5 s, top speed 310 km/h |

Official Site |

Sustainable Construction with Performance in Mind

For the first time in Ferrari’s history, both chassis and bodyshell are manufactured with 75 percent recycled aluminum, cutting approximately 6.7 tons of CO₂ per vehicle built. The structure employs short overhangs and an advanced driving position set close to the front axle for enhanced connection and visibility. The battery is fully integrated into the floorpan, with 85 percent of its modules concentrated as low as possible between the axles to minimize the center of gravity and optimize yaw and roll behavior.

Center of Gravity: 80 mm Lower than ICE

Ferrari cites a center of gravity 80 mm lower than an equivalent ICE model fundamental to EV agility and stability. This packaging choice, combined with a near-mid-ship mass layout, targets crisp turn-in, reduced body motions, and a planted stance at speed.

Noise, Vibration, Harshness (NVH) and the Separate Rear Subframe

In a first for Ferrari, the rear uses a separate subframe to decouple noise and vibration from the passenger cell while maintaining torsional rigidity. This subframe supports the high-output rear e-axle, inverter, and thermal systems. The result: refined cabin NVH without dulling the dynamic fidelity expected from a Ferrari.

Third-Generation 48 V Active Suspension

Evolving the system introduced on Purosangue and enhanced for F80, the third-gen 48 V active suspension manages vertical, roll, and pitch with rapid, predictive control. It optimally spreads cornering forces across all four wheels, improving ride comfort, body control, and tire contact key to delivering a natural, confidence-inspiring response on road and track.

In-House Electric Axles: Halbach Rotors and High Efficiency

Ferrari designs and builds both front and rear e-axles in-house, each using synchronous permanent-magnet motors with Halbach-array rotors an approach known for high power density and magnetic efficiency.

Front E-Axle (Selected Figures)

- Power at axle: 210 kW

- Torque at wheels: 3,500 Nm

- Motor speed: up to 30,000 rpm

- Power density: 3.23 kW/kg, 93% peak efficiency

- Inverter: >300 kW, fully integrated, ~9 kg

- Axle weight: 65 kg

Rear E-Axle (Selected Figures)

- Power at axle: 620 kW

- Torque at wheels: 8,000 Nm

- Motor speed: up to 25,500 rpm

- Power density: 4.80 kW/kg, 93% peak efficiency

- Inverter: >600 kW

- Axle weight: 129 kg

Together, the system supports >1,000 cv in boost mode, with highly efficient power conversion and precise torque vectoring potential.

Battery: High Energy Density, High Voltage, High Throughput

The Maranello-designed battery targets best-in-class metrics:

- Configuration: 210 cells (15 modules × 14 cells)

- Gross capacity: 122 kWh

- Pack energy density: ~195 Wh/kg

- Cell energy density: ~305 Wh/kg

- Max system voltage: 880 V

- Max DC charge power: up to 350 kW

A bespoke cooling system equalizes thermal load to maintain performance consistency under repeated high-power use, while the 880 V architecture shortens charging times and reduces I²R losses.

Headline Performance and Dimensions

Ferrari Elettrica – Technical Specifications (Selected)

Performance

- 0–100 km/h: 2.5 s

- Top speed: 310 km/h

- Power: >1,000 cv (boost mode)

- Range: >530 km

Dimensions and Weight

- Wheelbase: 2,960 mm

- Weight: ~2,300 kg

- Weight distribution: 47% front / 53% rear

These figures frame the Elettrica as an EV grand tourer with supercar-grade acceleration and long-legged range, backed by Ferrari’s trademark balance and control.

Driving Character: Precision, Feedback, and Confidence

Beyond numbers, Ferrari’s objective is a driving experience that feels decisive and communicative. The low CoG, active suspension, rigid structure, and efficient, high-response e-axles are tuned to produce linear controls, predictable rotation, and natural on-limit behavior core to Ferrari’s identity. The platform’s electronics are integrated to amplify driver intent rather than overwhelm it, a philosophy inherited from the brand’s top-tier hybrid programs.

FAQs: Ferrari Elettrica Platform

1) How powerful is the Elettrica?

Ferrari quotes >1,000 cv in boost mode, supported by in-house e-axles and high-power inverters.

2) What is the claimed range?

Ferrari targets >530 km, aided by a 122 kWh battery, 880 V system, and aerodynamic/thermal optimization.

3) What makes this platform “Ferrari”?

Nearly all key systems battery, e-axles, inverters, control software, chassis are developed and built in-house, with 60+ patents protecting solutions tailored to Ferrari dynamics and emotion.

4) How does the chassis improve sustainability?

The chassis and body use 75% recycled aluminum, cutting ~6.7 tons of CO₂ per vehicle.

5) How low is the center of gravity?

80 mm lower than a comparable ICE Ferrari, thanks to floor-integrated modules with 85% of cells placed at the lowest height.

6) What suspension does it use?

Third-generation 48 V active suspension, distributing cornering forces across four wheels for better comfort and control.

7) How fast can it charge?

Up to 350 kW DC on an 880 V architecture, with pack thermal management designed for peak repeatability.

8) Are the motors efficient?

Yes, both axles target ~93% peak efficiency, with Halbach-array rotors for power density and response.

Official Site

For announcements, technical insights, and model pages, visit:

Ferrari – Official Website

For More Information Click HERE